Furnaces

Heatmasters designs and manufactures high-quality custom-tailored industrial- and heat treatment furnaces for companies that have decided to invest in in-house heat treatment capabilities and know-how.

Each furnace is designed together with the customer, to ensure each furnace also meets current and future heating requirements.

Each furnace is designed together with the customer, to ensure each furnace also meets current and future heating requirements.

Contact Us

CONTACT US

X

Error: Contact form not found.

Benefits

Innovative Yet Simple Design

Our cutting-edge software and strong expertise in the heat treatment of metals, spanning half a century means our furnaces are user-friendly, durable, and well insulated. We believe in simple solutions, that always work whilst fulfilling your heat treatment requirements and international standards such as ISO 17663.

Complete Solutions

Furnaces require user training and testing/calibration of equipment. Furnaces built on-site will also require construction. Heatmasters constructs, tests, and provides all training to furnace clients on-site with over half a century of experience in the heat treatment industry. Of course, we provide flexible after-sales service and support to ensure smooth heat treatment operations for years to come!

Modern Control Systems

Our modern heat treatment process control software and controllers ensure the accurate results and documentation of the heat treatment process, whilst allowing easy operation on-site or remotely. Avoid using traditional thermal recorders, which have proven inaccurate in demanding conditions. The highest quality heat treatment furnaces require modern control systems such as the legendary Rigel + HM25 system from Heatmasters.

Read more

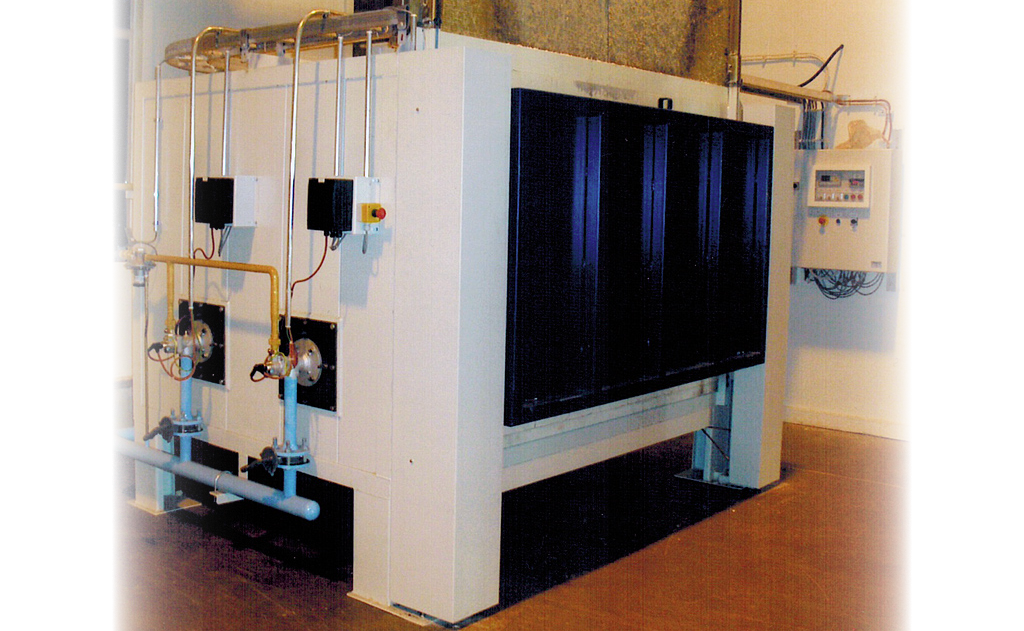

Efficient Electric and Gas Heating Options

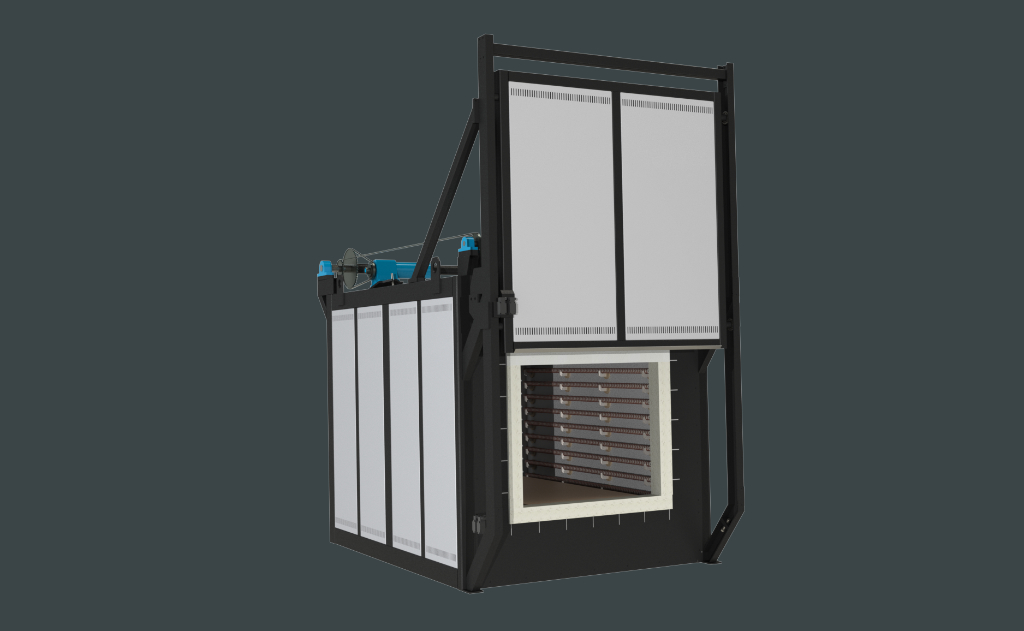

Heating for our furnaces is provided by electricity or gas. Each solution is highly optimized to provide evenly distributed, accurate and efficient temperatures. We also provide a thermal imaging service to ensure there are no leaks within the furnace.

Heat Treatment Furnaces

Heat treatment is a critical part of the metal fabrication processes, as it allows materials to gain desirable physical and mechanical properties without altering the shape of the component. Heatmasters has decades of experience operating, designing, delivering, and maintaining heat treatment furnaces.

Heatmasters delivers custom-tailored heat treatment furnaces, individually designed according to each customer’s specifications.

The most common furnace types delivered by Heatmasters include:

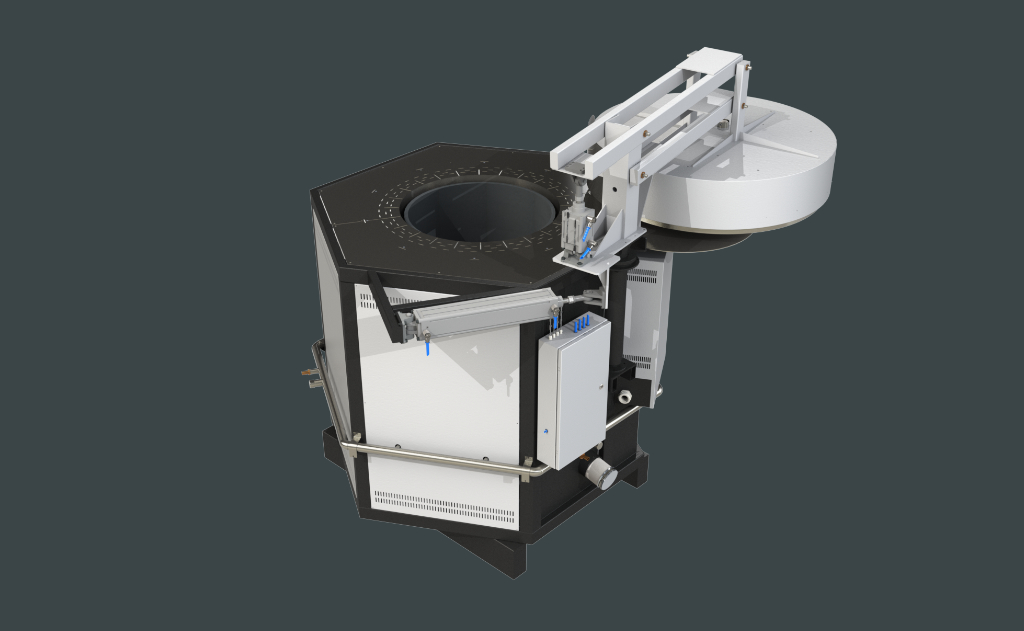

- Top Hat Furnaces

- Pivot Door Furnaces

- Forced Air Circulation Furnaces

- Chamber Furnaces

- Car Bottom / Bogie Furnaces

- Temporary Heat Treatment Furnaces

Contact Us

Applications

Our heat treatment furnaces are suitable for an extensive range of heat treatment processes, including:

- Annealing

- Hardening

- Quenching

- Stress relieving

- Normalizing

- Preheating

- Austenitizing

- Pearliting

- Ferriting

- Softening

View References

Industrial Furnaces & Other Industrial Equipment

Heatmasters also designs and delivers industrial furnaces and other equipment such as hot-dip galvanizing systems. All of our solutions are custom-tailored to meet the requirements of our customers. If you would like more information or would like to discuss your requirements, please contact our experts today.

Contact Us

Applications

Heatmasters designs and delivers industrial furnaces and equipment for applications such as:

- Drying

- Concentrate Drying

- Sintering

- Coating Processes

- Hot-Dip Galvanizing

View References

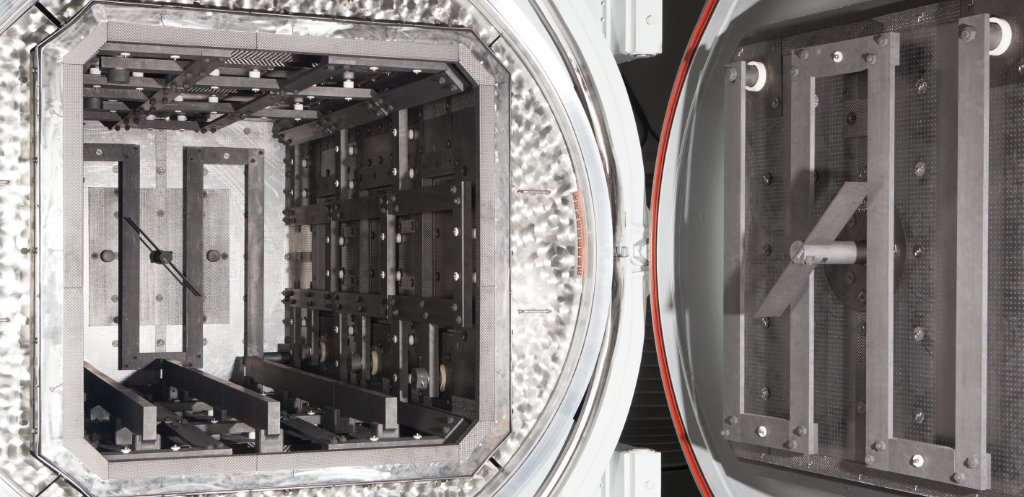

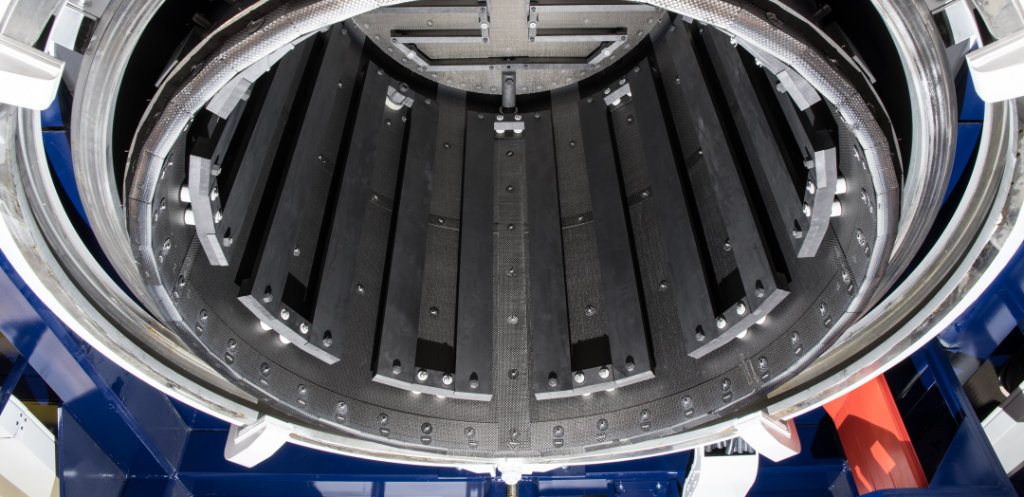

Vacuum Furnaces

Heatmasters delivers high-quality vacuum furnaces and life-cycle services to the Nordic region, specifically Finland, Sweden, and Norway.

Thanks to extensive knowledge of vacuum and high-temperature engineering as well as a large team of experts supported by the most advanced software and instrumentation, we provide state-of-the-art vacuum technology to our clientele. Our goal is to always provide reliable vacuum furnace solutions which meet the evolving process requirements of our customers across many industries and applications.

Are you interested in a vacuum furnace?

Don’t hesitate to contact our team of experts for more information.

Contact Us

Applications

Vacuum furnaces manufactured by TAV VACUUM FURNACES can be utilized for applications such as:

- Hardening

- Tempering

- Annealing

- Aging

- Nitriding

- Aluminizing

- Low-Pressure Carburizing

- Stress relieving

- Debinding & Sintering

- Additive Manufacturing

- Aluminium Brazing

- Vacuum Brazing

- Ceramics Processing

- Diffusion Bonding

More Information

Laboratory Furnaces

Heatmasters also provides high accuracy electric laboratory and muffle furnaces with internal capacities from 0,2 liters to 240 liters and continuous operating temperature ranges from 200 °C to 1600 °C. These furnaces are designed to meet the precise temperature control and temperature uniformity requirements for laboratory applications such as heat treating, sintering processes, materials testing and ceramic firing.

Contact Us

Applications

Heatmasters provides laboratory furnaces for applications such as:

- Materials Testing

- Hardening

- Loosening

- Normalizing

- Ceramic Firing

- Stoneware Firing

- Drying

- Thermal Testing

- Aging

- Preheating

There are various other applications which our furnaces can be utilized for. Our team is happy to help you find a suitable furnace to meet your requirements.